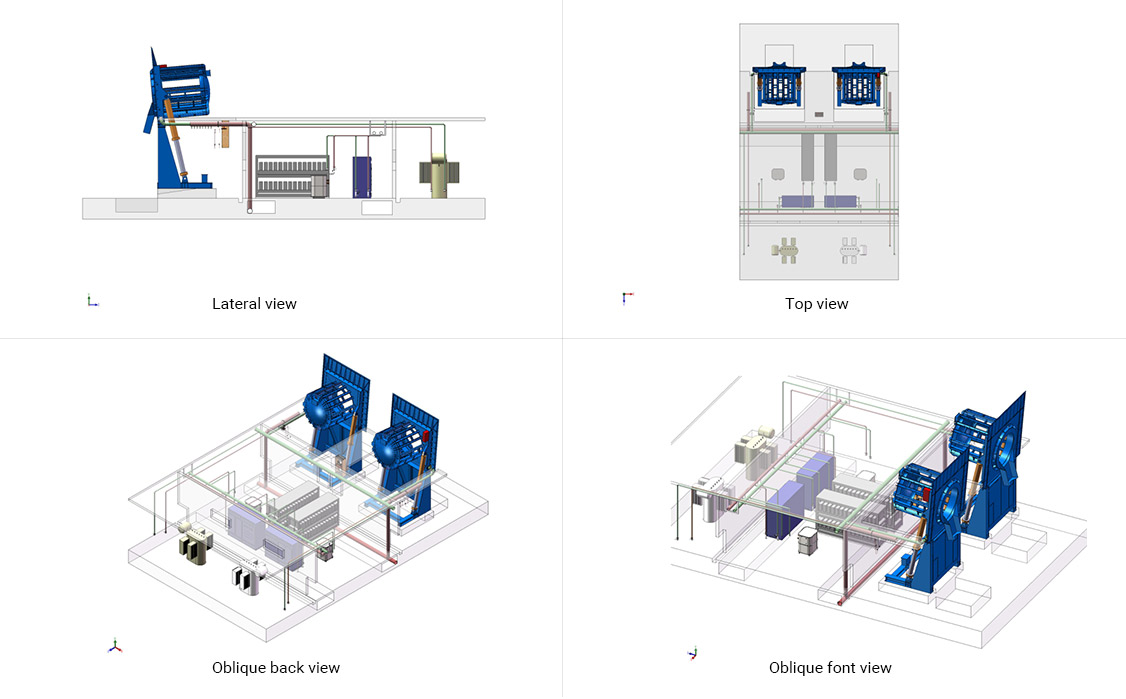

Schematic Layout of Complete Induction Furnace

The Features of Yinda Aluminum Alloy/Stainless Steel Melting Furnace

1,Advanced Design Concept of Energy Saving and High Efficiency

● IF Power supply 24 Pulse circuit design;

● Design of Inverter constant power circuit;

● High power preparation, rapid smelting;

● Optical fiber signal transmission, strong anti-interference ability;

● The sweep frequency-locked phase always tracks the best impedance frequency;

● Rectifier series, boost-down loss reduction;

● Load boost to reduce channel loss;

● Reasonable lining thickness, knotting, oven process and leakage alarm device;

2,Perfect Safety Protection Function

● Over voltage and current protection ● Pressure limit protection

● Load short circuit protection ● Circiut broken protection

● Average flow pressure protection ● Rectifier series, boost-down loss reduction

● Low frequency protection ● Three-phase phase-deficiency protection

● Misphase protection ● Water shortage protection

● Tip pulse absorption protection ● Fast fuse protection

● Leakage alarm device

3,Production Process of Quality System Assurance.

● Thick copper walls of induction coils

● The proper size and location of the short circuit ring

● Broader copper bar

● Larger section water cooled cables

● Appropriate length of slot cable and connection to reduce pressure drop

● Optimal installation of power supply, capacitor and furnace body

● All high current component wiring conforms to the principle of low current density

● High-strength mechanical design effectively contains vibration, prolongs life, and increases safety factor

● All resin casting of coils and reactors

● Optimal configuration of yoke

Metal/Aluminum Alloy/Stainless Steel Melting Furnace Manufacturers

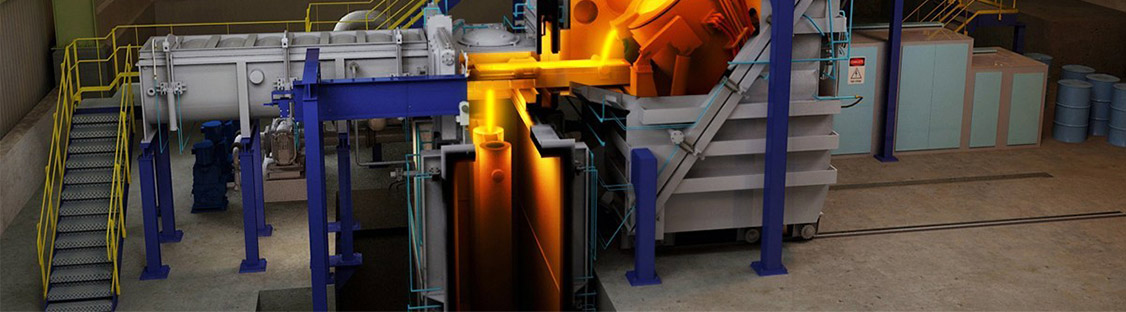

Hangzhou Yinda Electric Furnace Co., Ltd. is a manufacturing and service type enterprise which specializes in the design and production of all kinds of complete induction melting and heating equipment. custom Stainless Steel Melting Furnace manufacturers and Aluminum Alloy Melting Furnace Suppliers.Our company widely cooperates with the scientific research institutions both home and abroad and is devoted to researching and producing the complete equipment in induction heating, forging heating, heating treatment, quenching, soldering and brazing and another hot working field on the premise of taking the induction furnace (10kg-70T) as the leading product.

Yinda Metal Smelting Furnace manufacturers developed the domestic advanced series type dual power source variable-frequency power supply (known as one-to-two) after introducing, digesting, and absorbing the foreign advanced technology. The power supply is energy-saving with less harmonic content and high efficiency and has been widely applied in the foundry industry.

Our main products are GW series medium-frequency coreless induction furnace 10KG-70T; GWBZ series 1-150T medium-frequency coreless induction holding furnace; KGPSII medium frequency power supply series 50-35000KW(24 pulses low harmonic).

Among these, the KGPS type high-power medium frequency power supply 12000KW-35000KW and the 24 pulse rectification mode are first developed successfully by our company in China, and now these high-power supplies are mainly used for smelting as well as the warming and heating of large metal work-pieces(steel, copper, and aluminum, etc.) and profile(a pipe, board, belt, and stick, etc.)

English

English España

España EN

EN